electrical discharge machining puzzle

The hole drilling process involves using a brass electrode tube to channel the electrical discharges onto the material. Electric Discharge Machining EDM is a subtractive machining process that uses electrical current to.

Fabrication Vacuum Technology Inc

The Electrical Discharge Machining EDM is an unconventional.

. Electrical discharge machining EDM is a powerful nonconventional machining technique with the ability to machine any conductive material regardless of mechanical property. It is a process in which electrical energy is used to generate the Spark between the tool and workpiece submerged under the dielectric medium so that material. Electrical discharge machining is a highly precise manufacturing process that allows product teams to create complex shapes and depths that would be impossible to create using standard cutting tools.

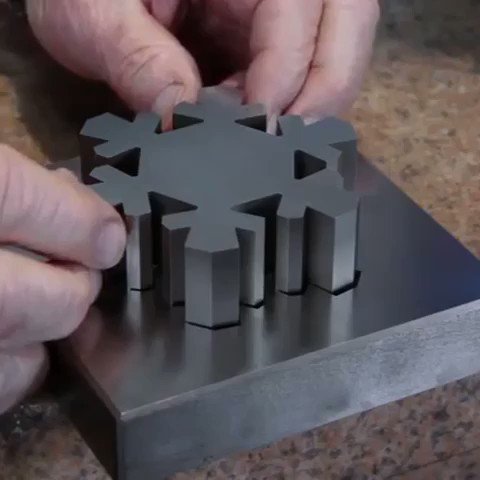

That allows the metal to be cut in such a precise way that two parts can merge seamlessly. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is obtained by using electrical discharges sparks. This is what I found out about how this is made.

In EDM or electrical discharge machining theyre not physically touching the parttheyre machining with lightning bolts literally sparks. Electrical discharge machining is an effective manufacturing solution for machining applications with high requirements. The electric spark produces intense heat of 14000 to 21500F.

Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques. With a top speed of mach 10 in 15 seconds the missile accelerated so fast that the blast doors had to be blown off. Also how this cube is made is practically black magic.

There is localized heating and vaporization in the machining zone due to which the workpiece is eroded and modeling of this erosion process helps in better evaluation of the material removal rate and temperature. However the sluggish nature of EDM stands out when the target is in mass production in industrial plants. This process is also named spark erosion machining or spark over initiated discharge machining as the removal of metal occurs due to erosion caused by the electric spark.

Known as EDM spark erosion technology Electrical Discharge Machining the manufacturing process solves the kind of machining puzzles that can stymy EDM deprived workshops. Electricity is zapped through it produces a spark. Electrical discharge machining tends to work to very tight tolerances of - 0012mm.

But some of us have to be electricians. It intends to provide an overview of how this process works when it should be used and what design considerations must be made. Electrical Discharge Machining was published by nttfdigitallibrary on 2017-12-02.

Your mission in this electrical puzzle is to light the evening city. Electrical discharge machining EDM is an unconventional machining process which is widely used in machining of complex geometries. More posts from the EngineeringPorn community.

In order to generate sparks between the electrode and the workpiece there must be a gap sometimes called discharge gap which is typically in the 0005 1 mm range. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by an interrupted. Lets delve deep into the technology the methods the applications and the.

Poor surface quality residual stress and heat-affected zone. Find more similar flip PDFs like Electrical Discharge Machining. This gap and the movement of the electrode are controlled by a servo mechanism on the EDM.

Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes separated by a dielectric liquid. What is Electric Discharge Machining. Extremely high precision CNC wire cut machine with a finish of 06 µ Ra.

EDM typically works with materials that are electrically conductive although methods have also been proposed for using EDM to machine insulating ceramics. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always harder than the work-piece. The use of a thermoelectric source of energy in developing the non-traditional techniques has greatly helped in achieving an economic machining of the extremely low machinability materials and difficult jobs.

This machining method comprises a dielectric medium tool a source power supply of voltage 50 450 V speed reduction gear-box a rack and pinion and an. Electrical discharge machiningEDM cuts metal using a superfine brass wire. Not only do we have the ability to wire cut with precision but we have the metrology lab to back it up and provide.

Quickly attach together a contact out of numerous wire pieces and get a faerie electrical discharge. If the electrode and the workpiece are in contact then sparks are not produced. This is a significant characteristic that makes it applicable in the aerospace and medical industries.

The term EDM stands for Electrical Discharge Machining. The process of material removal by a controlled erosion through a series of electric. But today could be that.

Introduction to Electric Discharge Machining EDM. Northern Gauge has the capability to wire cut EDM pieces with 400 x 300 mm XY range and with a Z axis range of 250mm. The blasts come with extremely high frequency something like 20000 sparks per second along the.

The Sprint missile was a thermonuclear interceptor designed to intercept anything below 37 miles. Also the cutting tool applies the force to remove the material from the work-piece during machining. Electrical discharge machining is a quick and unique way to create accurate deep small holes drilling in materials regardless of their hardness.

Gaze Upon the Black Magic of Electrical Discharge MachiningITS NOT EVERY day that industrial machining sends you into a fit of joy. This helps to create holes of various small dimensions. EDM also offers a superior surface finish and enables product teams to work with expensive metals while mitigating material loss costs.

Spark machining uses electrical discharge energy to subtract metal from a workpiece. Check Pages 1-50 of Electrical Discharge Machining in the flip PDF version. Everybody wants to be a superhero.

High Quality Wire Cut Edm Wire Cutting 25mm 25mm Skd11 Steel Puzzle Parts Milling High Polished Buy Wire Cut Edm Edm Wire Wire Edm Wire Product On Alibaba Com

Amazing Cube And Sphere Made By Wire Cut Edm Machine Youtube

Electrical Discharge Machining Leads To These Perfectly Fitted Steel Puzzles R Engineeringporn

Zero Tolerance Machining With The Wire Edm Making A Puzzle Cube Part 2 Us Digital Youtube

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Mitsubishi Wire Edm Puzzle Pieces Youtube

Metmo Cube Experience Metal In Motion Metmocube Com

Oh Wow Watch A Bunch Metal Shapes Created Using Electrical Discharge Machining Fit Together Seamlessly Dr Wong Emporium Of Tings Web Magazine

World Of Engineering Sur Twitter Amazing Accuracy Of Electrical Discharge Machining Wire Edm Can Cut With Accuracies Of 0001 00254 Mm Worldofengineering Engineering Technology Edm Machining Source Reliableedm Youtube Https T Co

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Wire Edm Electric Discharge Machining Medical Tooling Machining Hitachi Cable America

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Wiron Cube Wire Edm Puzzle Pieces Wackycompany Com

Community Challenge 12 Puzzles Closed 18 By Gg314 Contests Carbide 3d Community Site

Gaze Upon The Black Magic Of Electrical Discharge Machining Wired

Electrical Discharge Machining Allows For A Perfect Fit Between Metal Pieces R Engineering